Tube Inspections accurately examine heat exchanger tubes to detect damage or defects wherein ensuring the tubes are safe to continue use. INTERGY provides a comprehensive inspection program consisting of multiple tube inspection techniques to determine the integrity of your heat exchangers. Eddy Current Testing (ET) Our standard Eddy

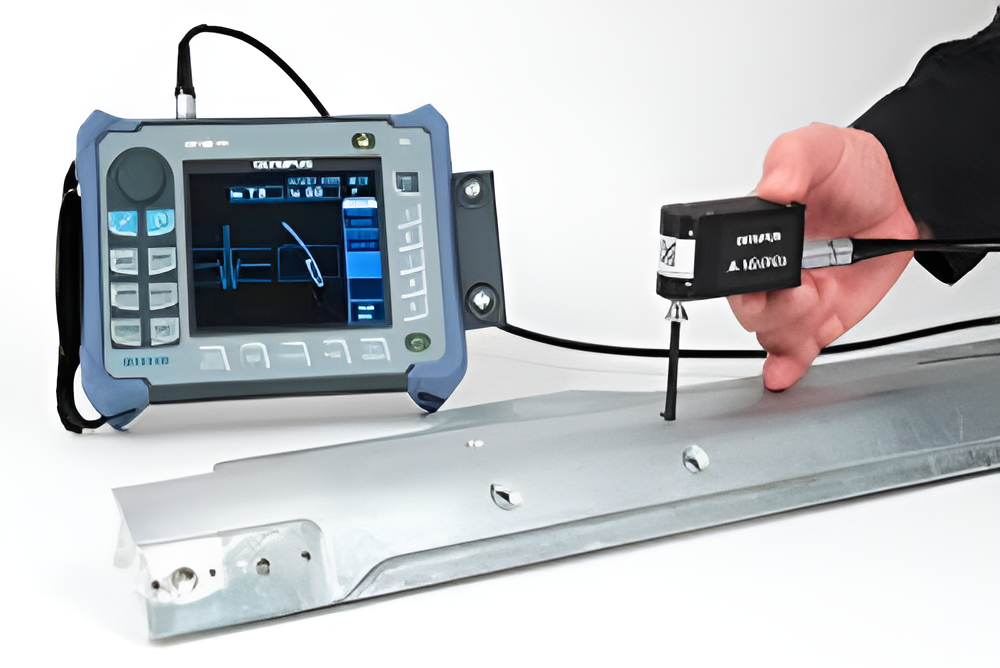

PHASED ARRAY ULTRASONIC TECHNIQUE Phased Array Ultrasonic Testing (PAUT) is an advanced nondestructive examination technique that utilizes a set of ultrasonic testing (UT) probes made up of numerous small elements, each of which is pulsed individually with computer-calculated timing

Video Borescope is a remote visual examination technique/tool for determining the presence of internal defects including internal cracks, intensity of corrosion or erosion, oxidation or internal deposits, degree of damage, pitting and presence of foreign objects etc. In any directly inaccessible area of component through Inspection hole, tube cutting opening and its other integral parts etc.

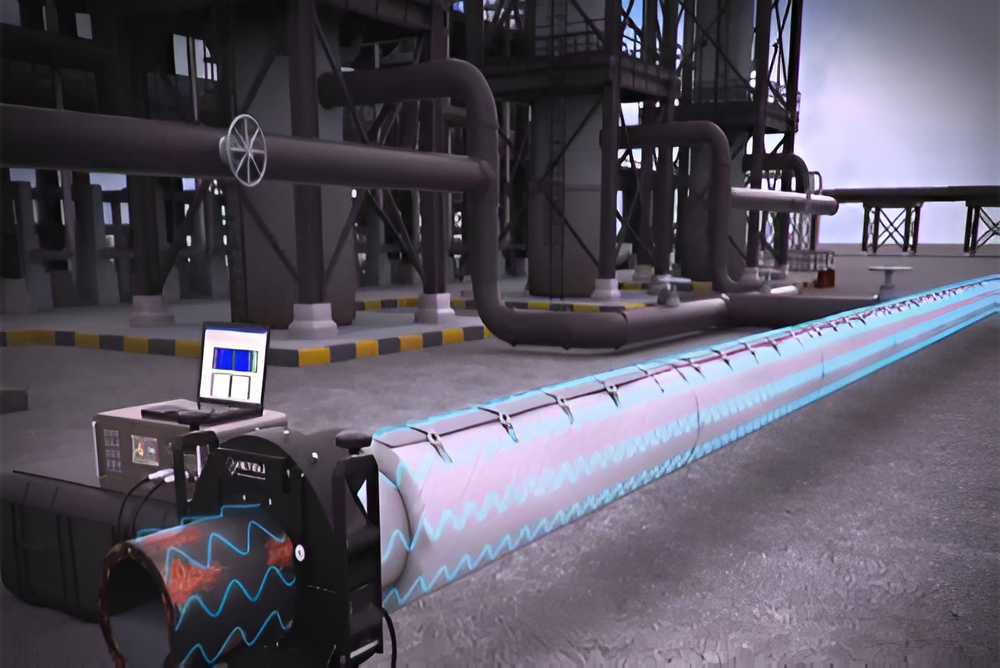

Long range ultrasonic testing is a rapid way of screening for corrosion in above ground and underground pipelines, boiler furnace tubes etc. The method enables screening of up to 100 meters of pipeline in one test, i.e. 50 meters in both directions. By fitting a ring of transducers around the pipeline, a wave maker device directs low frequency (20-100 kHz) ultrasonic waves

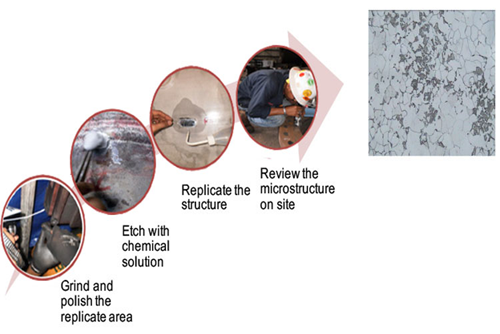

As an NDE technique, Replica Testing ( In-Situ Metallography) is ideal for assessing the remaining life of power and petrochemical plants. INTERGY Ltd, has qualified and experienced field services team that regularly conducts In-situ Metallography on-site at major plants, refineries and process industries. This team from Massa determines in-service degradation of

Eddy current testing can be used for a wide range of applications. It is often applied for surface crack detection and material sorting. Material sorting is used to ensure that the proper materials are in use and to verify component materials or assembly features (such as the orientation or position of a subcomponent in an assembly). Flaw Detection It’s usually carried out with pencil probes or ‘pancake’ type probes

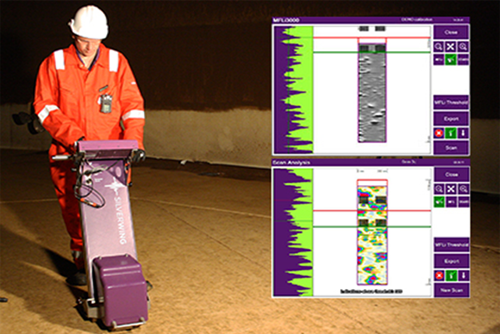

The tank floor inspection and integrity support using the Floorscanners is combined with the advantageous Saturation Low Frequency Eddy Current technique. The Floorscanners are capable of inspecting with high speed floor plates up to 30mm and penetrating through coating up to 10mm thick. They are also

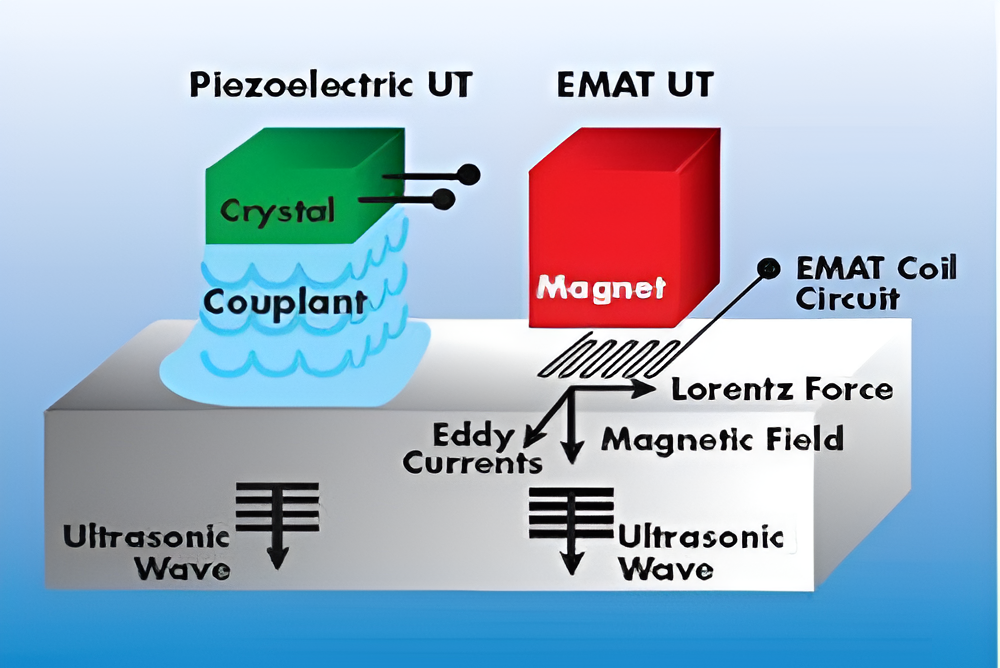

EMAT or Electro Magnetic Acoustic Transducer is an Ultrasonic Testing (UT) technique that generates the sound in the part inspected instead of the transducer. An EMAT induces ultrasonic waves into a test object with two interacting magnetic fields. A relatively high frequency

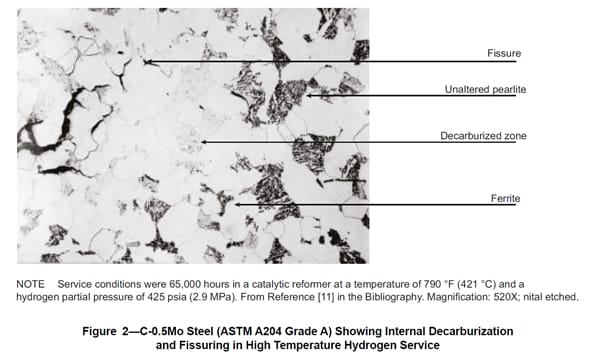

High-temperature hydrogen attack (HTHA) is a damage mechanism that affects aging assets, including vessels, hydrocrackers, and heat exchangers in the petrochemical industry. It occurs when hydrogen molecules contained in a liquid or gas hydrocarbon penetrate steel

Pulsed Eddy Current Testing (PECT) is an inspection technique used for corrosion under insulation (CUI) screening on carbon steel structures as pipes, vessels, tanks and spherical tank legs without the need of contact with the steel surface.

Company

(+20) 1067260212

(+20) 01006126531

info@intergy.org

location

8B, Sakalya Street

Nasr City, Cairo , Egypt

©intergy, All rights reserved, Product by wpaper agency PureSoft