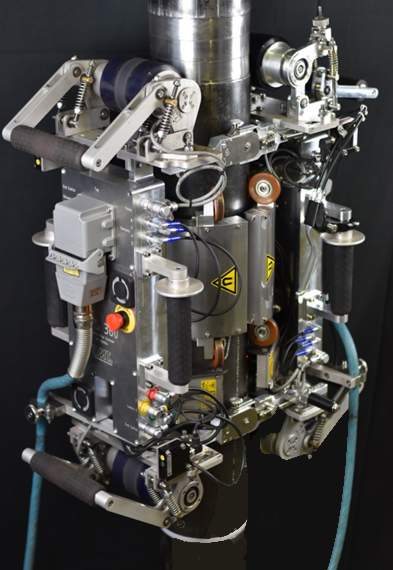

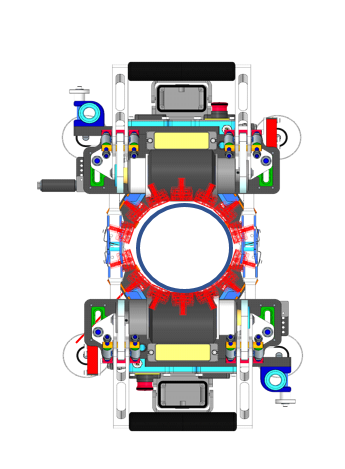

One of the most important tasks for a reliable operation of reformer furnaces is the integrity of the reformer tubes. The early detection of creep damage and micro-cracks using the Reformer Pipe Scanner (RPS 360) proprietary OD and ID inspection systems can lead to improved reformer tube knowledge and operation. The diameter is measurement by laser for expansion and is performed simultaneously with our proprietary 360° crack detection system.

As exclusive agent & representative of KnotrollTechnik in Egypt & MENA regions, we bring the long experience, know-how and competence in eddy current Technology and job enforcement.

This competence is featured by KontrollTechnik´s steady efforts in research and development of state of the art of testing procedures and equipment.

RPS 360 OD

RPS 360 ID

Company

(+20) 1067260212

(+20) 01006126531

info@intergy.org

location

8B, Sakalya Street

Nasr City, Cairo , Egypt

©intergy, All rights reserved, Product by wpaper agency PureSoft