About us

INTERGY provides highly technical support to worldwide clients in the Syn Gas and petrochemical industry supporting ammonia and urea, methanol plants

Years Experience

0

+

★★★★★ 4.7/5

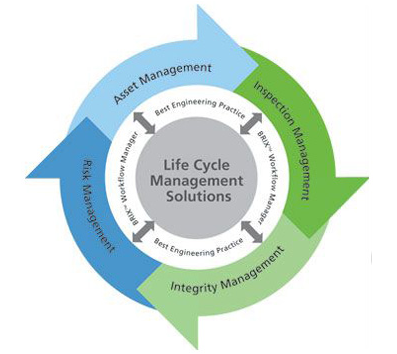

INTERGY focuses on wholistic solutions which address the root causes of poor or unexpected performance and can assess and optimize plants with our unique multi-discipline entity and experience shared through our partners.